3D Printing and Injection Molding: A Perfect Pair for New Product Development

In the evolving world of manufacturing, staying ahead means embracing innovation without losing efficiency. Whether you’re an established manufacturer or an innovator bringing bold new designs to life, your product’s success requires agile prototyping and a strategy for transitioning to production. By combining 3D print prototyping with scientific injection molding for proven production, manufacturers can launch new products quickly, with minimal risk.

The Complementary Relationship Between 3D Printing and Injection Molding

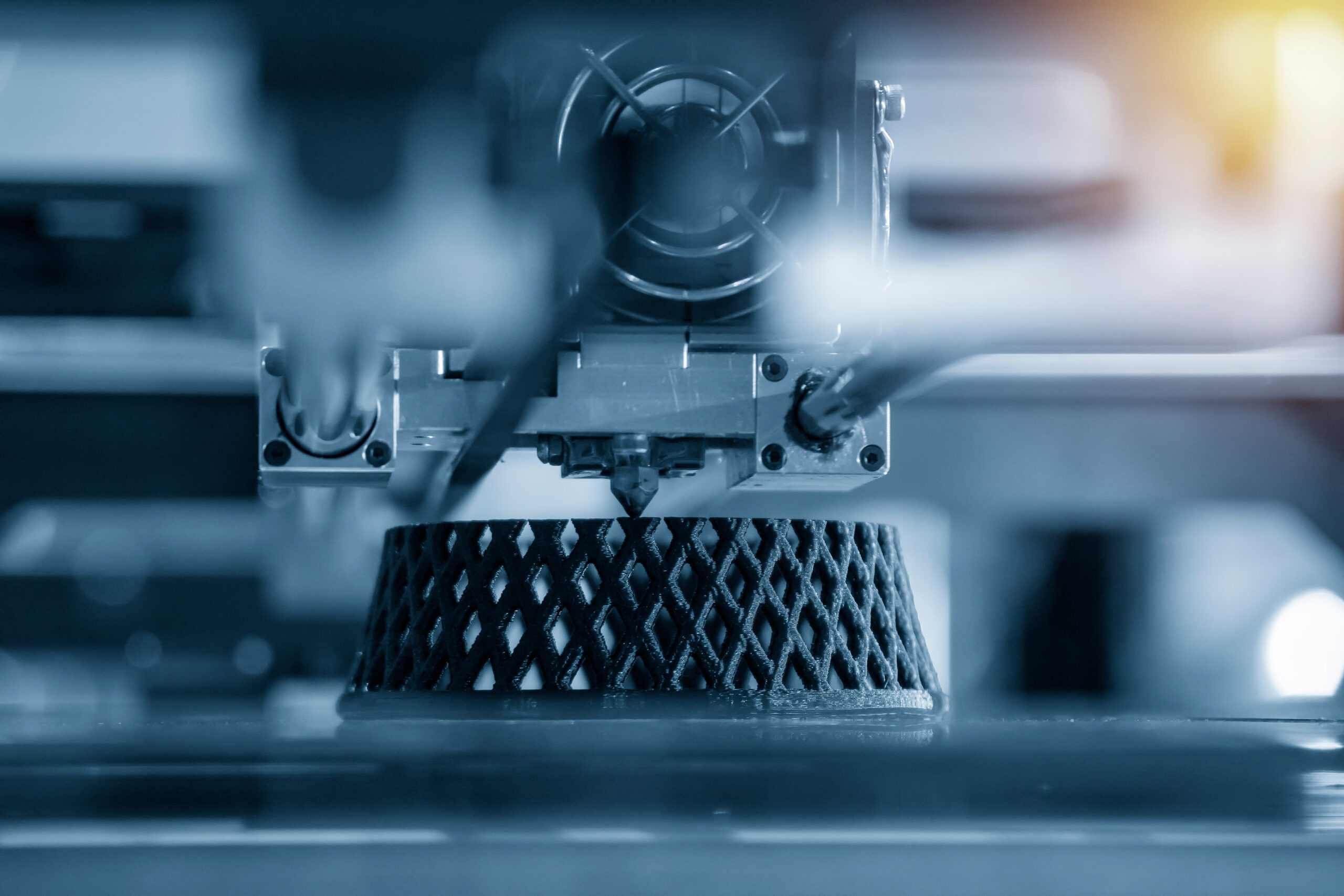

3D printing—or additive manufacturing—has redefined what’s possible in prototyping through its speed, flexibility, and precision. Its ability to produce intricate designs in a fraction of the time required by conventional methods allows for rapid iteration—letting engineers refine, rethink, and improve in real time. Beyond prototyping, it can also be a highly cost-effective production option for low-quantity or complex parts, reducing waste and supporting more sustainable development cycles.

Rather than viewing 3D printing and injection molding as competing technologies, today’s most successful manufacturers treat them as a powerful pairing. By beginning with 3D printing, teams can validate designs quickly and affordably, revealing issues long before expensive tooling begins. Before a prototype can move into production, however, it must be evaluated through the lens of injection molding.

Validation is Vital to the Process

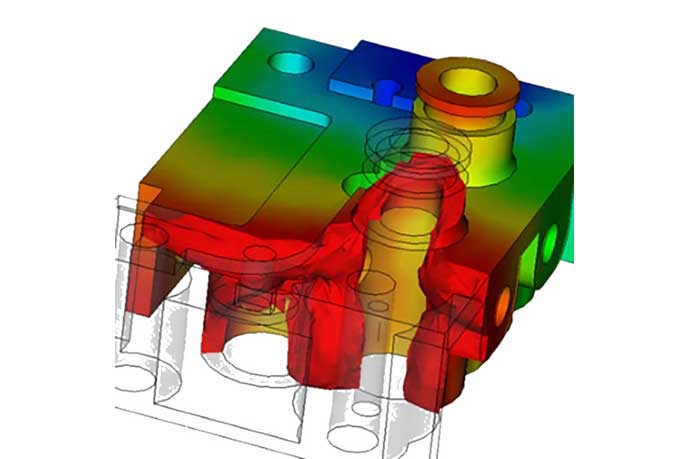

While 3D printing excels at proving out form, fit, and function, it doesn’t inherently account for key molding realities like shrinkage, tooling constraints, and the flow of molten resin. Before finalizing a design for production, manufacturers must validate prototypes to ensure they translate seamlessly into moldable, high-quality parts.

Effective design validation by a team that understands both technologies helps catch common pitfalls early. These include:

- Gate and runner planning: Printed prototypes don’t need gates, but molded parts do—and poor gate placement can cause cosmetic defects, uneven fill, or structural weaknesses. Considering gating early shortens the transition to tooling.

- Part geometry and draft requirements: Features that print well may stick in a mold or require additional draft. Validating geometry ensures parts eject cleanly and reduce wear on the tool.

- Tolerance and shrink considerations: A printed part may hold tight tolerances that resin molding can’t naturally reproduce without adjustment. Anticipating shrink and compensating in the design prevents costly tooling revisions.

- Wall thickness optimization: 3D printing tolerates inconsistent or overly thick walls, but injection molding requires uniformity for proper filling, cooling, and part strength. Verifying print prototypes for moldability prevents warping or sink marks later.

Moving from Prototype to Production

Once a prototype has been proven through 3D printing, when should you shift to injection molding? The decision typically hinges on production volume and cost targets. As demand increases, injection molding becomes the clear choice, offering the economies of scale needed for efficient, high-volume production.

A successful transition involves thoughtful planning: Select the right materials, ensure the design is optimized for molding, and partner with an experienced tool maker and injection molder. When done well, this shift preserves design integrity, improves efficiency, and sets the stage for streamlined mass production.

Cost and Time Efficiency Benefits

The combination of 3D printing and injection molding unlocks significant gains in both cost and time. Early prototypes produced through additive manufacturing are inexpensive and fast, allowing designers to experiment freely without straining budgets. And because design flaws are addressed early, the injection molding process benefits from fewer tooling changes and longer-lasting molds—lowering long-term production costs.

Time savings are equally impactful. With rapid iterations made possible by 3D printing, companies can accelerate development cycles and reach the market faster—an invaluable edge in today’s competitive landscape.

The partnership between 3D printing and injection molding is driving innovation across industries. In the medical sector, teams quickly prototype custom implants and surgical instruments before scaling them for clinical use. Consumer electronics companies use the combination to bring sophisticated device housings and components to market more efficiently. From automotive to aerospace, the synergy is reshaping how products move from idea to production.

3D Printing Prototype Service Considerations

Integrating 3D prototyping into your workflow isn’t without considerations. Choosing the right materials and technologies can be complex, and the upfront investment in industrial-grade printers may give teams pause. That’s why collaborating with knowledgeable partners—those who understand both prototyping and manufacturing—is key to avoiding common setbacks and making the most of each technology’s strengths.

For many manufacturers, the challenge isn’t recognizing the benefits—it’s finding a partner who can expertly and seamlessly handle both prototyping and production.

Choose New Berlin Plastics to Optimize Your 3D Printing and Injection Molding Experience

New Berlin Plastics is the lowest-risk, highest-value partner you can choose to make the process smooth, efficient, and cost-effective. We combine rapid 3D-printing capabilities with deep expertise in high-quality injection molding, helping you validate designs quickly and transition to production with confidence. Our proven processes, disciplined project management, and commitment to risk reduction ensure your parts are engineered for success at every stage—from early prototypes to full-scale manufacturing.

If you’re ready to bring your next product to life, New Berlin Plastics can guide you through the entire journey. Contact us today to explore materials, tooling options, and production strategies tailored to your goals.