Page 1 of 16

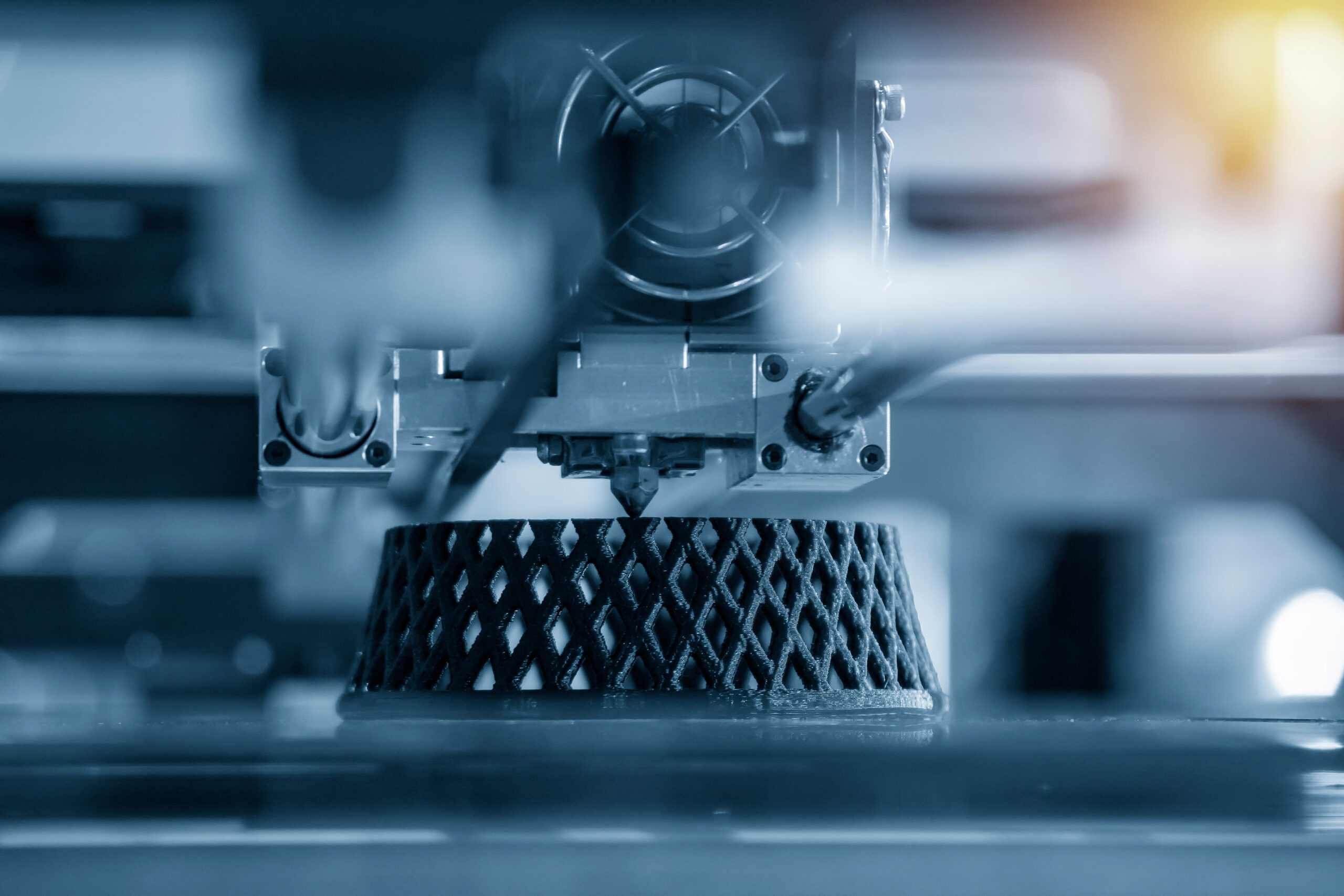

3D Printing and Injection Molding: A Perfect Pair for New Product Development

In the evolving world of manufacturing, staying ahead means embracing innovation without losing efficiency. Whether you’re an established manufacturer or an innovator bringing bold new designs to life, your product’s success requires agile prototyping and a strategy for transitioning to production. By combining 3D print prototyping with scientific injection molding for proven production, manufacturers can…

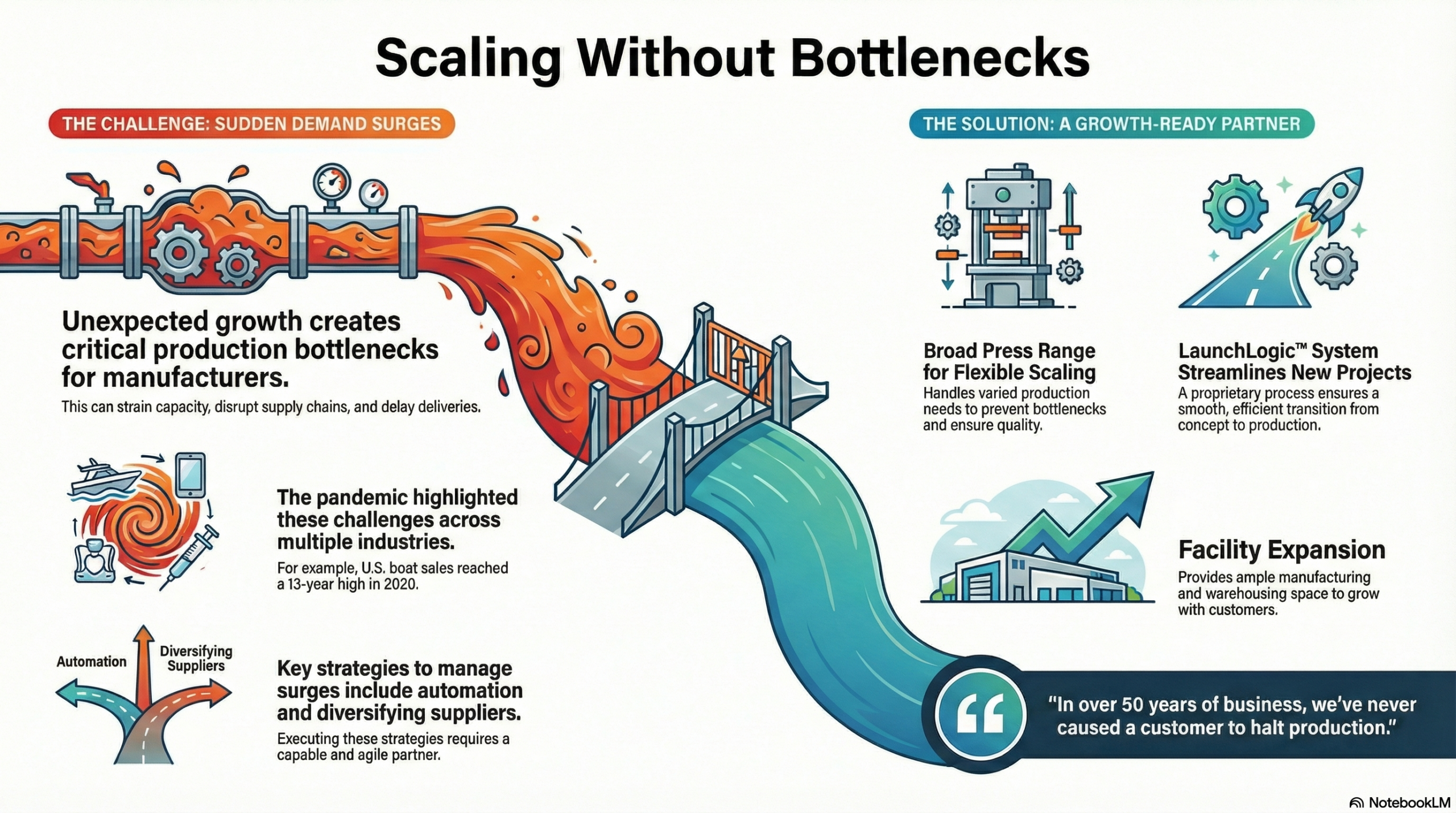

Podcast – Scaling Without Bottlenecks

Rapid growth and skyrocketing demand sound like a dream for most businesses, but it can quickly become a nightmare if production can’t keep up. We uploaded our New Berlin Plastics growth strategy for scaling without bottlenecks and then asked Google’s NotebookLM to generate a podcast for our customers’ listening enjoyment. Listen to the podcast now!…

Podcast – Injection Molding Partner for Supply Chain Resilience

Hear how OEMs can mitigate supply chain risks in an unstable global market simply by selecting the right supplier. We gathered a collection of the most relevant New Berlin Plastics articles and then asked Google’s NotebookLM to generate a podcast for our customers. Listen to the podcast now! Among other things, the podcast advises OEMs…

Weathering Resin Price Swings: How Partnerships Keep Manufacturers Moving

Understanding Resin Price Volatility Resin price volatility is driven by a combination of supply chain disruptions, global energy costs, and shifts in demand. When oil or natural gas prices rise, resin costs tend to follow. Severe weather events, plant outages, transportation bottlenecks, or geopolitical conflicts can further tighten supply. Adding to the uncertainty, strong demand…

Scaling Without Bottlenecks: OEMs Need Growth-Ready Strategies

For original equipment manufacturers (OEMs), growth can happen fast—and bring unexpected challenges and opportunities. As product demand rises or new market opportunities emerge, the ability to scale production while avoiding bottlenecks, maintaining quality, and meeting delivery deadlines becomes a critical competitive advantage. This was exemplified during the pandemic, when certain sectors experienced remarkable demand increases.…

Privately Held Suppliers Offer Unique Advantages to Manufacturers

In a sluggish market, manufacturers need suppliers for timely delivery, quick adaptation, and high-quality standards. Privately held suppliers offer advantages over those under private equity or group ownership, providing stability and long-term support. Free from the pressures of servicing debt burdens or short-term investor demands, they are better able to focus on sustainable growth and…

Putting it All Together: Standalone Plastic Part Assembly Service

Selection teams in the manufacturing industry understand efficiency is critical for smooth and profitable operations. Those whose products require even light plastic part assembly or kitting face a number of challenges in achieving optimal efficiency. From handling inventory to ensuring quality control to keeping complex processes on schedule, manufacturers dealing with part assembly processes navigate…

OEMs Mitigate Risk by Onshoring Custom Plastic Injection Molding

Manufacturers who rely on injection molded plastic components can’t afford having their production lines go down because a partner fails to deliver on time. That’s why the most successful supplier selection teams regularly evaluate all risks in their supply chain and weigh them against the benefits their suppliers provide. In the past, offshoring injection molding…

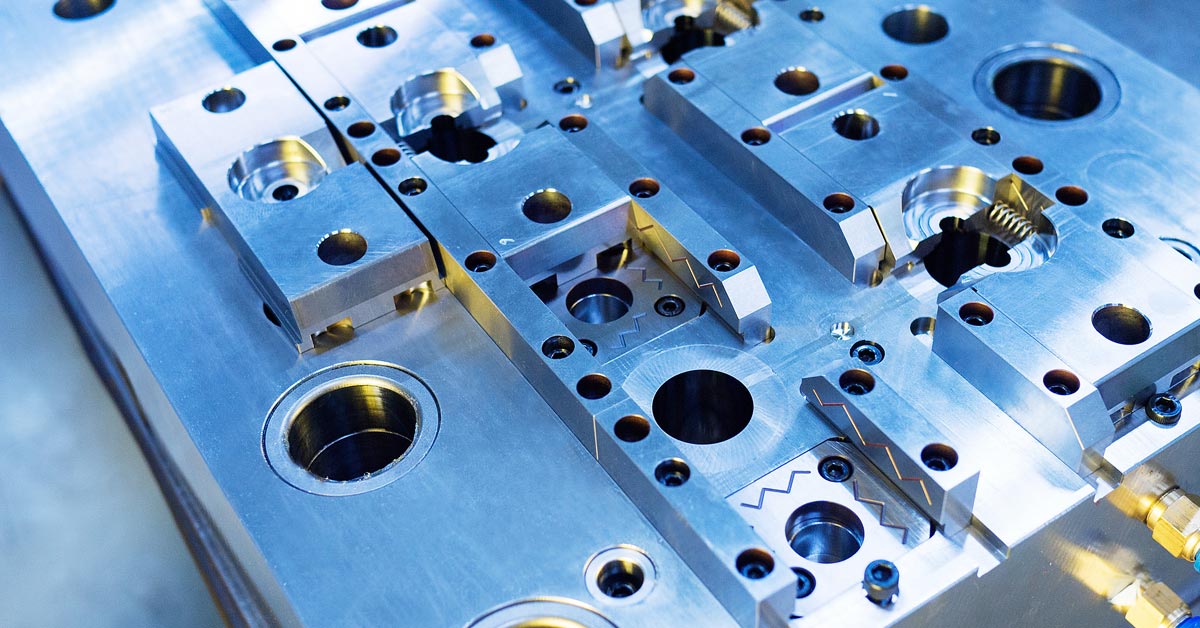

Making Complex Geometry Parts with Advanced Injection Molding Technology

Not long ago, there were limited options for making plastic parts that have complex geometries. A common method was CNC machining, which can be expensive and slow. Plastic injection molding is a much faster and cost-effective way to make parts, but those with intricate designs can cause quality and processing challenges. However, New Berlin Plastics…

Page 1 of 16